ANSON WELLHEADS

ANSON design and manufacture a wide range of Wellhead assemblies for use with all well service conditions and all types of completions with working pressures up to and including 20,000 psi at operating temperature ranging from -75 ̊F up to 400 ̊F. All Anson Wellhead systems are designed and manufactured in accordance with API 6A requirements as a basic minimum.

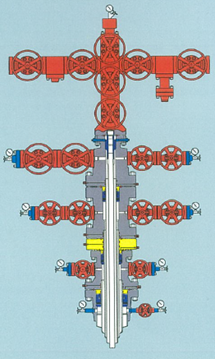

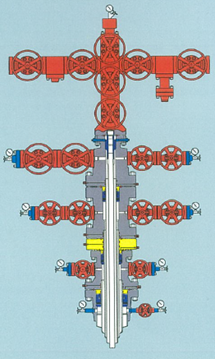

The ANSON type F wellhead system features slip type casing hangers for use in casting heads and spools and mandrel tubing hangers to seal and suspend tubing strings. Type F wellhead spools feature a straight bore top bowl design with a 45 ̊ load shoulder. A range of secondary seals and packoffs can also provided adding to the wellheads versatility.

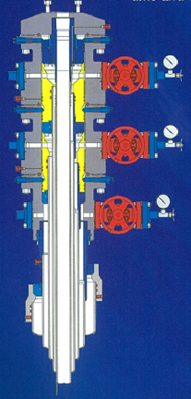

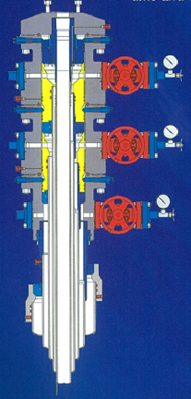

The ANSON type F-TB thro’ bore three-stage wellhead system offers a simple and reliable assembly for use where safety, flexibility and reduced rig down time is important.

The three stage assembly is designed to accept mandrel or slip type casing hangers and their packoffs.

All casing and tubing can be installed, landed and sealed thro’ the BOP stack, saving rig time and with increased safety.

All three stages can be installed as a single unit or split as drilling conditions demand.

ANSON can also supply a full installation, maintenance and training service to suit the customers needs.